In just a handful of years, the battery-based energy storage industry has evolved from single MW proof-of-concept projects to 200+ MW utility-scale systems. Now recognized globally for its pivotal role in enabling the clean energy transition, battery storage is entering a new era of project scaling to help the world maintain grid reliability as renewable deployment accelerates.

As storage is rapidly deployed around the globe, the industry must address the lifecycle impact of these systems. Of particular importance is integrating circular economy principles to close the loop in the storage product lifecycle and, in doing so, enhance overall supply chain sustainability.

In this article, we delve into the concept of circular economy, exploring how embracing circularity in the lifecycle of storage products can enhance sustainability while fostering resilience and innovation. Join us as we uncover the strategies and benefits of closing the loop in the utility-scale energy storage supply chain.

Understanding the Circular Economy

The traditional linear economy can be viewed as a straight line from extracting raw materials, turning them into products, and eventually discarding them as waste. Currently, a mere 7 percent of utilized materials are cycled back into the economy. This take, make, and dispose model places immense strain on our environment, exacerbating issues related to climate change, biodiversity loss, and pollution.

Enter the circular economy – a regenerative system designed to redefine how we produce, use, and dispose of products. A circular economy keeps materials and products in circulation for as long as possible. The circular economy represents a paradigm shift toward minimizing waste and fostering sustainable utilization of natural resources through strategic approaches like intelligent product design, prolonging product lifespan, efficient recycling practices, and regenerative measures. Additionally, the circular economy holds promise in addressing multifaceted co-occurring global crises such as climate change and biodiversity loss.

In the context of utility-scale energy storage, a circular economy approach means examining the entire lifecycle of energy storage systems, from raw material extraction to end-of-life disposal. When viewed through the circular economy lens, each step in the storage product lifecycle brings the opportunity to contribute to a more sustainable manufacturing ecosystem. Circularity also fosters innovation, encouraging forward-thinking approaches to product design and business models to manage end-of-life sustainably.

Now that we understand the difference between a traditional linear economy and a circular economy let's examine the critical stages of a storage product's lifecycle through the circular economy lens.

Fluence Circular Economy Framework in Action: Design, Usage, and Digitization

Refining Product Designs

Energy storage systems are critical in integrating renewable energy sources into the grid, managing peak demand, and ensuring stable power supply. However, the design of these systems holds far-reaching implications beyond mere functionality. It directly influences their environmental footprint, lifecycle efficiency, and potential for circularity. Efficient and thoughtful product design minimizes resource consumption and waste generation throughout the lifecycle of energy storage systems.

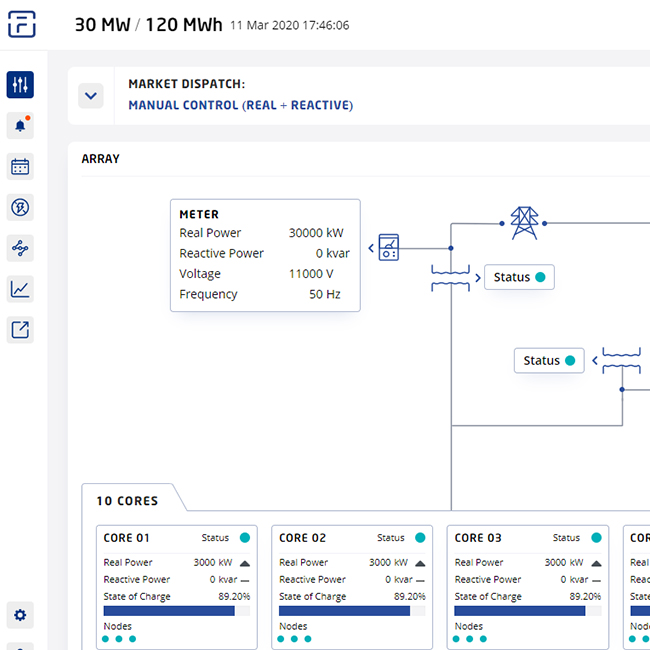

Designing storage products for modularity allows components to be easily upgraded, refurbished, or replaced, extending the overall lifespan. Modular system designs can increase the efficiency of transporting storage products from manufacturing plants to the field while reducing construction timelines. As shown through Fluence's large-scale fire tests, modular designs can also help improve product safety and minimize system damages if a fire event occurs.

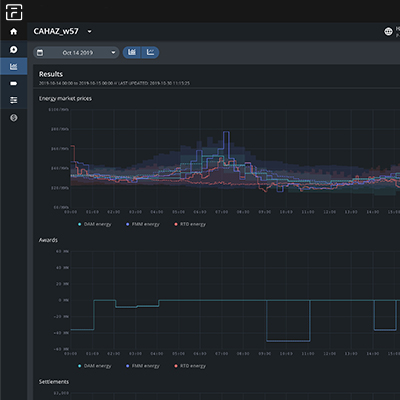

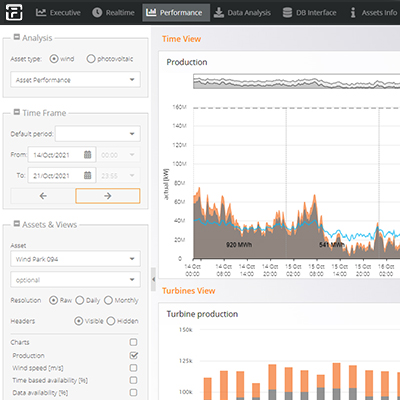

Further, product design plays a crucial role in optimizing the performance and efficiency of energy storage systems, thereby enhancing their overall sustainability. Integrating smart technologies and sensors enables real-time monitoring and predictive maintenance. This helps ensure optimal performance and eased reparability throughout the product's lifecycle while minimizing downtime and unnecessary maintenance activities.

Improving Efficiency in Manufacturing

Circular economy manufacturing best practices focus on resource efficiency, waste reduction, and maximizing the value of materials throughout their lifecycle. These practices aim to minimize the consumption of finite resources and reduce environmental impact.

By streamlining production processes and optimizing supply chains, manufacturers can lower the overall cost of energy storage technologies, thereby accelerating their adoption and deployment. This, in turn, can stimulate market growth and encourage further innovation in the sector, helping to drive the transition towards a more sustainable energy future.

Existing Gridstack Production, Utah, USA

Since 2021, Fluence has invested in regionalizing our manufacturing operations to address regional challenges and reduce environmental impact. This strategy is intended to ensure we are supporting customers worldwide. Fluence is also gathering product sustainability data from our product component and battery module manufacturers to more aptly understand and respond to the specific environmental impact of our energy storage products. For example, module manufacturers are beginning to provide Fluence with third party verified figures on their per-unit emissions as well as recycled and recyclable content. This effort allows us to find opportunities to continuously improve and work to mitigate environmental impacts.

Embracing Recycling and Reuse

While recycling minimizes waste's environmental impact and helps create a closed-loop system that continually repurposes materials, there are still significant end-of-life challenges facing the utility-scale energy storage industry. Some of the most pressing industry challenges include:

- Disassembly can be risky and challenging for large batteries in a critical condition. This presents issues with safely repackaging, transporting, and recycling damaged battery packs.

- Transport of batteries is challenging and expensive. Access to recycling facilities in the country where the system is produced, and within reasonable distance, is important to mitigate export challenges and high shipping costs.

- Recovery of lithium is not standard in the recycling industry and will be essential given the adoption of Lithium Iron Phosphate (LFP) as a standard battery chemistry. Battery recycling is optimized for Nickel Manganese Cobalt (NMC) chemistries today, and the economic incentive to recycle LFP is much lower due to the commodity’s value.

- Without proper recycler checks in place, it's also not guaranteed that damaged batteries are sent to recycling, but instead illegally disposed or traded overseas. Illegal disposal is one of the biggest risks with recycling LFP batteries.

- Lack of information about battery state of health down to a cell level, at the point of recycling, increases challenges around battery reuse. Reuse is only viable if there is strong confidence in the battery condition. Verification of this is not an easy process.

|

Fluence partners with Li-Cycle for recycling damaged batteries at Fluence-controlled locations in the Americas and EMEA. Li-Cycle’s two-step process can recycle lithium-ion batteries of all chemistries and enables up to a 95% recovery rate. |

As a step towards overcoming these challenges, forward-thinking companies are developing comprehensive recycling and repurposing programs to try to ensure that batteries are safely and efficiently disposed or reused. By recovering valuable materials from spent batteries and reintroducing them into the production cycle, these initiatives reduce the environmental impact of energy storage systems and create new economic opportunities.

Fluence is partnering with recycling companies that are ISO 9001 and 14001 certified that are taking a structured and third-party audited approach to sustainability and that are focused on continuous improvement of their environmental footprint and quality management practices. Additionally, we have initiated our material recycling framework, including internal policies that mandate and facilitate battery recycling through partnerships with companies in North America, Europe, and Australia. These policies promote the responsible handling and potential reuse of battery module materials upon replacement. We plan to continue to build new recycling partnerships throughout the world and develop a full site decommissioning procedure to promote responsible behavior and accountability when storage products end their first operational life.

Promoting Second-Life Applications

Rather than viewing end-of-life energy storage systems as obsolete, a circular economy mindset encourages exploring second-life applications. Batteries that no longer meet the demands of utility-scale storage can find new life in less demanding applications, such as stationary energy storage for homes or businesses. This second life not only extends the product's overall lifespan but also reduces the demand for newly mined materials as well as the environmental burden of disposal.

We recognize that our energy storage solutions have the potential for a second life. As such, we plan to develop a future second-life framework that will combine aspects of Fluence's material recycling and responsive design frameworks. The overarching goal of this framework will be to provide our products with a second life before final deconstruction and recycling.

Collaboration for a Circular Future

Achieving a circular economy in the utility-scale energy storage industry requires collaboration across the entire value chain, from manufacturers and suppliers to engineers and recyclers. By partnering with stakeholders at every stage of the lifecycle, stakeholders can identify opportunities for improvement, implement best practices, and drive collective action toward a more sustainable future. Additionally, industry-wide initiatives and standards can help streamline efforts and ensure consistency in sustainability practices.

For example, Fluence works closely with our suppliers and customers to promote and uphold responsible business practices at each point in our product lifecycle. We also offer customer-centric sustainability programs and initiatives designed to engage and educate customers on the environmental and social impact of their choices.

In addition, we recognize that Fluence's suppliers are a critical element of our sustainability strategy. We maintain a robust responsible sourcing framework that is intended to enhance engagement with Fluence's suppliers and align them with our sustainability initiatives. Find more information about this framework and our responsible sourcing strategy in our FY 2023 Sustainability Report.

Fluence's Responsible Sourcing Framework

By joining forces, we believe that stakeholders can amplify their impact and drive the transition towards a more circular and sustainable energy storage sector.

Closing the Loop for a Sustainable Tomorrow

The circular economy is not merely a theoretical concept but a practical and achievable framework that promotes better stewardship, responsibility, accountability, and transparency. As the demand for utility-scale battery storage continues to rise, our industry faces challenges and opportunities in implementing circular economy principles. By embracing innovation, collaboration, and a commitment to closing the loop on the product lifecycle, all stakeholders are empowered to reduce their environmental impact, drive economic growth, and create value for society. Together, we can pave the way for a more sustainable future.

Want to learn more about Fluence's circular economy framework, which is structured to guide our products' design, operations, and recycling?

The blog is subject to Fluence’s disclaimer’s regarding forward-looking statements.