At Fluence, innovation drives our mission to transform the way we power our world by delivering industry-leading energy storage solutions. Our process is rooted in proactive research, customer feedback, and strategic foresight. We consistently push the boundaries of performance, efficiency, and value creation for our customers. But what guides these efforts, and how do we decide which battery technologies to bring to market? In this blog, we will explore how Fluence approaches technology prioritization and development and how our teams seamlessly integrate our offerings to maximize customer value.

Identifying and Prioritizing New Battery Technologies

Prioritization of battery technologies begins with a thorough understanding of market dynamics and our customers' needs. We work closely with battery manufacturers and continuously monitor advancements in energy storage components. Our specialized teams track innovations in storage technologies, particularly lithium-ion, while exploring emerging alternatives such as sodium-ion and solid-state batteries. We actively engage with over 30 battery manufacturers, analyzing their technology roadmaps and assessing how their advancements can enhance system performance and deliver better value to our customers. These insights guide our decisions on which technologies to invest in, with a focus on those demonstrating a clear path to commercial viability within the next two to five years.

Evaluating New Technologies

Once potential technologies have been identified, our teams evaluate multiple factors, including relevance to customer applications, technical maturity, and market competitiveness, to ultimately determine which innovations will deliver the most value. When a technology reaches Technology Readiness Level (TRL 6-7)—meaning it has advanced beyond lab testing and is ready for real-world testing—Fluence may support developers in assessing system-level implications through pilot projects. For technologies with a clear path to production within two to three years, Fluence conducts a rigorous evaluation, including design and factory audits, reviews of early test results, in-house cycle testing, and performance modeling. These processes are crucial, as many battery technologies must meet stringent operational requirements, such as long lifecycle performance (15-20 years and 8,000-11,000 cycles), which are difficult to test in real-time prior to market launch.

Research & Development Process Centered on Evolving User Needs

Bringing New Technologies to Market

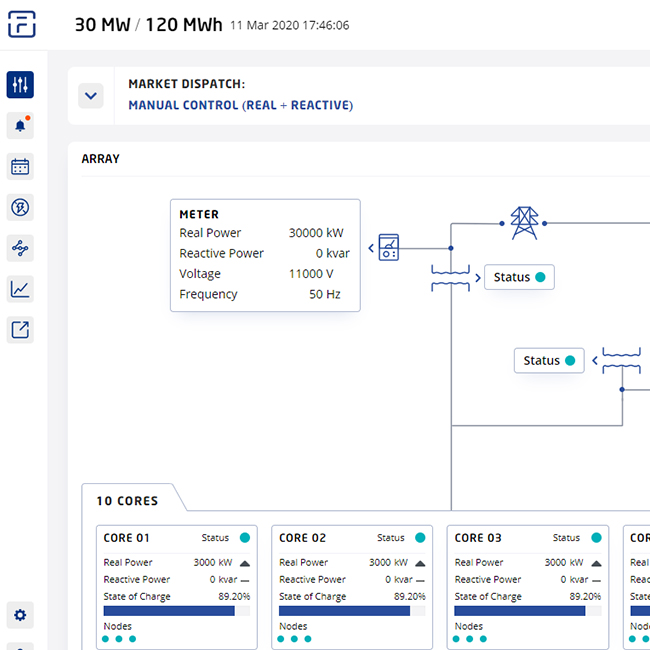

Once a new technology is identified as viable, we determine the market segments and use cases where it will bring the most value to our customers and define the solution that will leverage this technology. We then initiate a product development program that moves through our stage-gate process, advancing from concept and initial product launch to system validation, certification, and production ramp-up. Our quality management system plays a pivotal role in this process, involving rigorous supplier and performance audits at each step, from design to commissioning.

Ensuring compliance with regulatory and industry standards, as well as our own quality and safety requirements, is critical to bringing new storage technology to market. At Fluence, our compliance team continuously monitors these standards, integrating them as core requirements during product development. In the early stages, our engineering and compliance teams work closely with storage technology suppliers to verify and document compliance at the component level. Throughout the system development phases, the compliance team collaborates with Fluence test labs and external certification agencies to rigorously test, validate, and certify the entire system. This comprehensive compliance process must be completed without exceptions before systems are shipped to customer sites. Upholding our commitment to ethical practices, we prioritize partnerships with suppliers who meet our standards, evaluating them against key ESG criteria—such as labor practices, environmental policies, and corporate social responsibility initiatives—as part of our responsible sourcing policy.

Overcoming Challenges in Technology Adoption

One of the main challenges in adopting new storage technologies is validating long-term performance. Energy storage systems must meet stringent lifespan requirements, making it difficult to fully test new technologies to their end-of-life before market launch. To address this, we rely on accelerated degradation testing and advanced simulations that model performance from the particle level to the system level. This enables us to uphold our industry-leading safety and quality standards.

What Emerging Trends Present Opportunities for Fluence?

In the near term, we anticipate that lithium-iron phosphate (LFP) batteries will continue to dominate the energy storage landscape. Key advancements are emerging in cell and enclosure density, life cycle, and overall performance, particularly with the adoption of pre-lithiation techniques, enhancing the robustness and efficiency of LFP. Sodium-ion (Na-ion) batteries are also progressing well, showing promise for utility-scale applications with targeted cost and cycle life capabilities, though their density remains lower than LFP.

While future technologies—like solid-state lithium, lithium manganese iron phosphate (LMFP), and lithium nickel manganese oxide (LMNO)—could redefine energy storage, they are still a few years from meeting the necessary criteria for utility-scale adoption. Other alternatives, such as nickel hydrogen, all-iron flow, and iron-air batteries, may present cost advantages over lithium-ion and sodium-ion solutions but currently lack the density, discharge rates (C-rates), and round-trip efficiencies needed for competitive energy storage markets. However, they may carve out new niche applications as they mature.

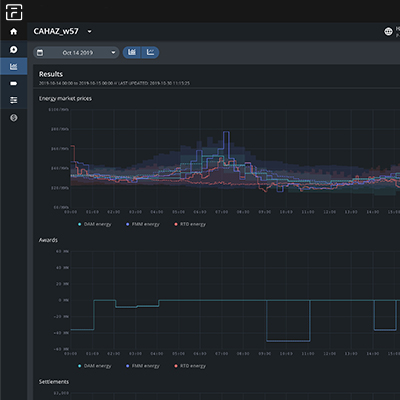

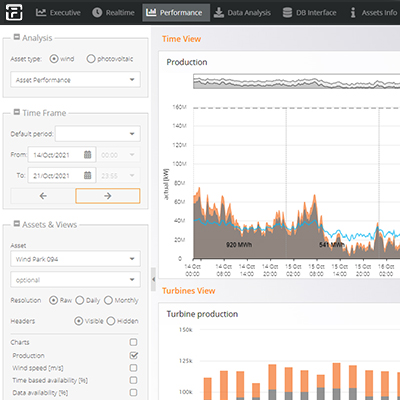

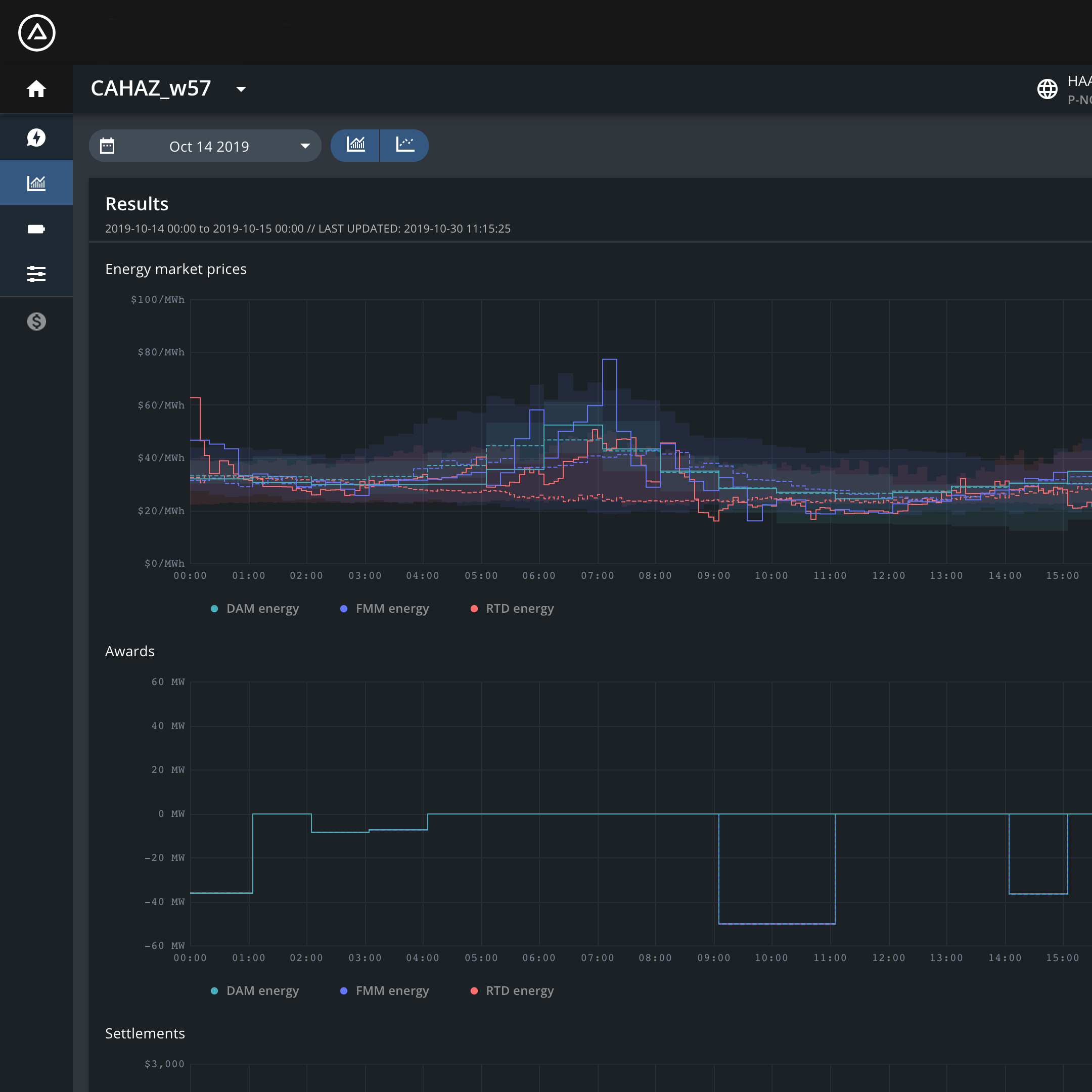

As battery technology levels across the industry, Fluence’s advantage will lie in our strength in system integration and software. The trend toward fully productized systems is simplifying installation and commissioning processes, significantly boosting project returns, enhancing customer satisfaction, and accelerating energy storage adoption. Additionally, the focus of Fluence’s revenue generation is shifting from battery enclosure sales toward servicing the expanding installed fleet. By leveraging AI and digital tools to optimize predictive maintenance and operations and maintenance (O&M), Fluence is well-positioned to lead in storage digital solutions and services, combining market-leading software and expertise with robust functionality that drives meaningful value for customers.