Safety first, and the view that every accident is preventable, are foundational beliefs at Fluence. These beliefs are built into every aspect of our organization. Beginning with the first grid-connected lithium-ion battery system we installed in 2008, our team has focused on driving safe practices in the design, implementation, and operation of energy storage systems.

Safety is a particular concern for companies in an industry that deals daily with the inherent dangers of managing electricity and is an active topic in the energy storage industry today. Fluence is constantly focused on reducing that danger by identifying risks, developing ways to mitigate them, and promoting practices that advance safety for ourselves, our customers, our communities, and the industry.

Our latest 6th generation tech stack, which was just announced in June, incorporates lessons learned from 12 years of real-world experience embedded into the integrated hardware, software, and digital tools. The 6th generation technology includes stringent safety features, which meet the most recent safety standards such as NFPA 855, UL9540, and UL 9540A non-propagation testing. We realize that standards must continually evolve, and we continue to work closely with the National Fire Protection Association (NFPA) and others to incorporate new information and make both our technology and processes as safe as possible.

Safety in Technology

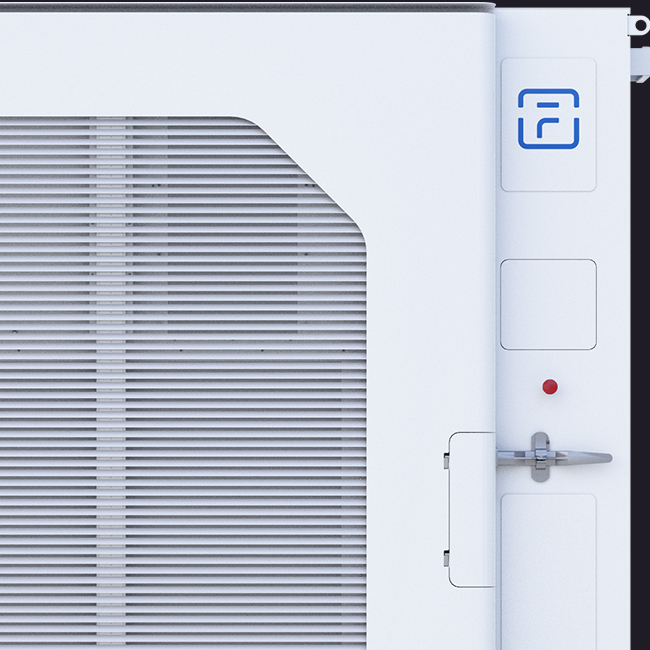

The Fluence Cube is a modular, factory-assembled approximately 8x8x8 foot cube-shaped enclosure that is configurable with the latest energy storage technology and safety equipment. The design is 4-5 times more modular than traditional containerized solutions, providing operators with greater flexibility and compartmentalizing battery modules within each enclosure. The Cube is designed for external access and cannot be entered. In the event of a fire, the Cube will electrically isolate itself and is designed to limit propagation to any adjacent Cubes. If a safety incident occurs, a fire strobe and alarm will be triggered to alert people that the sensors in the Cube detect an abnormal condition, and signage on the enclosure will alert first responders not to open the Cube.

Each Cube is outfitted with an incipient gas detection system that will detect gases created by heating and/or chemical processes in the cells. Upon detecting gases, the system will trigger an emergency shutdown, electrically isolating any affected batteries. Every Cube has an emergency stop functionality that can be triggered by the Cube hardware, Fluence OS (operating system), or an operator or first responder.

Cubes are equipped with a fire suppression system to prevent the spread of non-battery fires to the batteries. The Cubes use batteries which have demonstrated non-propagation of single cell thermal runaway in UL 9540A testing. In the very unlikely event of propagating thermal runaway that causes batteries to release combustible gases, deflagration panels compliant with NFPA 68 are built into every Cube to direct the force of any pressure up and away from humans. The pressure release serves to minimize structural and mechanical damage, and more important, to minimize the safety risk to operators or first responders.

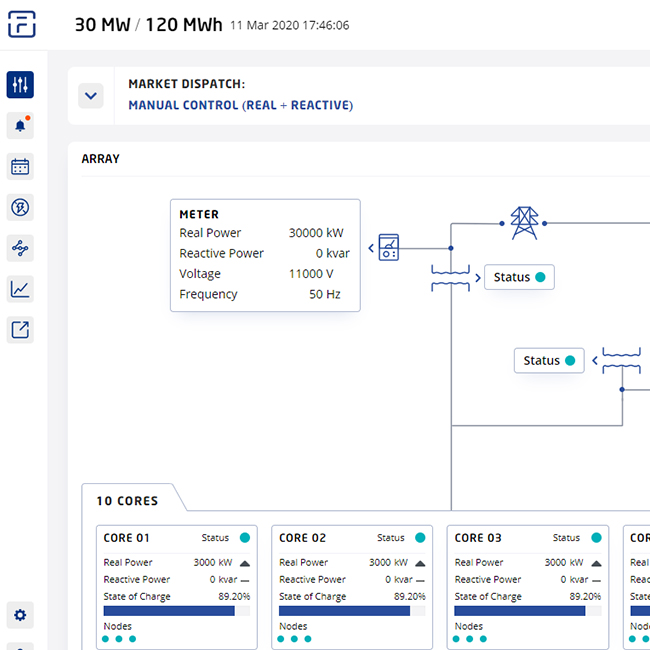

Furthermore, the Fluence OS continuously monitors for possible anomalies in the system and alerts operators to them. Potential problems are isolated and flagged for immediate attention, including alerts to Fluence’s 24/7 monitoring staff. Certain patterns, such as deviations in cell voltage from the rest of the module, trigger an immediate emergency stop.

Safety in Processes

Fluence’s internal product development and quality management processes are rigorous. Our product development teams regularly review emerging codes and standards, industry best practices, potential safety issues, new customer requests, and lessons learned from the field. We then apply the lessons learned to current customers and future designs. Our design and review process involves both internal Fluence domain experts as well as external safety and engineering professionals. Our quality management process also involves regular review and root cause analysis of any safety issues and incidents to avoid similar issues in the future.

Strong operating and response processes for energy storage systems are crucial elements of overall system safety. Fluence provides operational and safety training with all the systems we design and install, including working with the system owner on outreach to local first responders. We provide site emergency action plan templates and related information to assist owners in the completion of their own site-specific response plans. An important element of these plans is to ensure the owner has a clear process for removing people from the immediate vicinity of the system during an emergency event and for supplying critical information to first responders so they are not in harm’s way.

Fluence also continues to drive safety improvements for the industry by working with the National Fire Protection Association (NFPA), regulators, and industry associations to enhance industry standards; speaking publicly about what we have learned; and developing additional outreach to firefighters and first responders.

Continual Learning

Fluence has a long track record of operating energy storage systems safely and reliably in a wide variety of physical environments. We know that sustaining this record requires continued vigilance and learning, and we actively seek out areas where we can raise the bar, learning from our experience and the experience of others as we strive to transform the way we power our world to create a more sustainable future.